In the realm of portable and wearable medical technology, patients and healthcare providers now have access to safer and more flexible tools that can collect vital biometric data and facilitate care. These innovative products often rely on pogo-pin connectors, which are essential components in ensuring reliable and durable connections.

As the healthcare industry evolves towards new methods of delivering care, the demand for portable and wearable medical devices is rapidly increasing. These products empower patients with greater independence, flexibility, and support, providing critical and timely information to healthcare providers, thereby enhancing diagnostics and patient care. Portable medical technologies can be utilized both at home and in healthcare facilities, where they gather and transmit valuable data to the cloud for storage and analysis by medical professionals.

To meet the growing need for secure and effective portable products, connector design engineers are developing smaller, more robust connection solutions suitable for compact medical designs. In addition to their compact size, these connectors must be sturdy enough to withstand daily vibrations, impacts, and general usage conditions typical of portable and wearable medical applications used in both domestic and institutional settings. They also need to resist exposure to fluids, including cleaning chemicals. Robust spring-loaded waterproof pogo-pin connectors offer high performance and are crucial for portable and wearable medical applications.

Portable and wearable medical devices, such as glucose monitors, are becoming increasingly prevalent, often requiring smaller and more durable connection components compared to those used in clinical settings.

Application Background

The global pandemic has accelerated the demand for safe, automated, and portable home medical technologies. The global market for wearable medical devices was valued at $10.3 billion in 2018 and is projected to grow to $93.7 billion by 2027. Wearable monitors, including blood glucose meters, insulin monitors, and heart rate monitors, play a vital role in proactive prevention and patient care. To ensure practicality and durability in typical use scenarios, these electronic devices must be adequately protected against everyday hazards, including exposure to liquids and dust. Pogo-pin connectors serve as a durable and efficient connection solution.

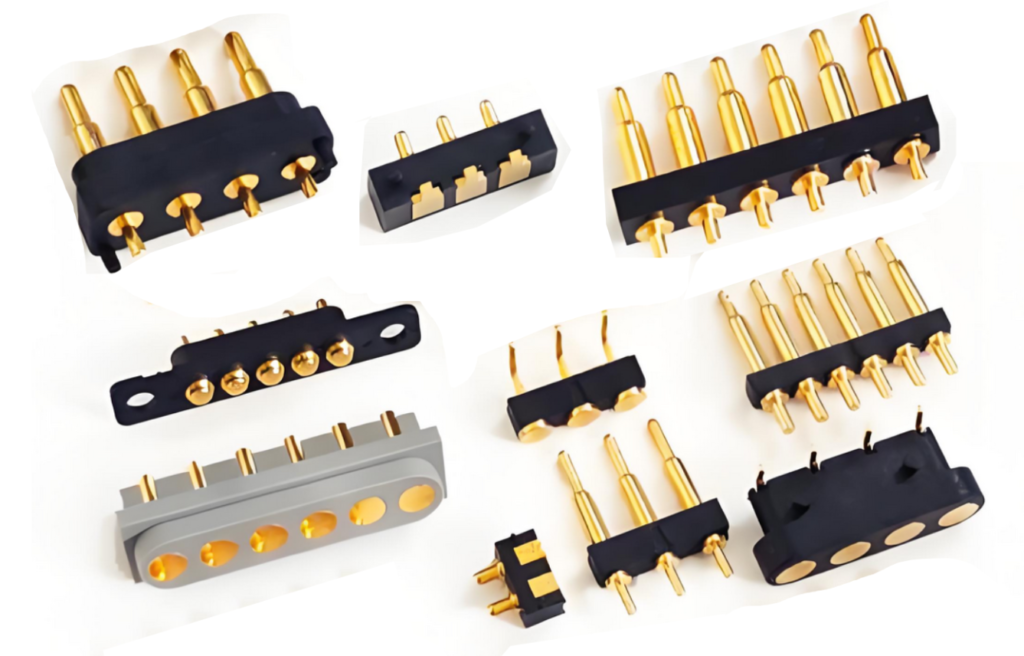

Structure of Pogo-Pin Connectors

A pogo-pin connector consists of three primary components: the pin, tube, and spring. The spring-loaded design applies constant lateral pressure inside the tube, offering a more stable connection and better contact resistance compared to standard connectors.

The floating contact design of pogo-pin connectors allows for free rotation and sliding within the housing, providing the necessary range of motion. They eliminate the need for soldering, significantly reducing assembly time and costs, and feature easy-to-remove spring pins that maximize design flexibility. Additionally, they are typically gold-plated to achieve high electrical conductivity, enhance durability, and improve corrosion resistance.

Spring-Loaded, Waterproof Bracket Connectors

The mobile parts of the pogo-pin structure usually allow liquid to come into contact with the pin through gaps. However, by altering the orientation of the pogo-pin within the housing and adding rubber seals, the male end (e.g., bracket connectors) can effectively prevent leakage.

Environmental Protection

Like most connectors used in portable and wearable medical devices, pogo-pin connectors can provide IP-rated water resistance to prevent liquid ingress. In spring-loaded connectors, this is achieved by installing O-rings between the contact pin and the housing. For example, the Yokowo S Series offers IP67, IP68, or IP69K protection against water, steam, cleaning chemicals, and other liquid contaminants.

Durability and Reliability

Insufficient connectivity can negatively impact the performance of portable medical devices, potentially leading to severe consequences for patients and operators. Due to the high, constant mating force provided by pogo-pin contacts, they can withstand shocks and vibrations, maintaining strong and reliable connections even under harsh conditions.

Waterproof spring-loaded connectors exhibit excellent durability, a critical advantage for frequently assembled and disassembled products like portable medical diagnostic and imaging equipment. Advanced vacuum-coated pogo-pins are suitable for vacuum environments, featuring bleed holes on the side or bottom of the tube. Each surface is uniformly coated to ensure maximum durability. As a result, vacuum-coated pogo-pin connectors can withstand up to 100,000 mating cycles.

Size

Recent advancements in manufacturing capabilities have enabled the development of extremely small-diameter waterproof pogo-pins. New waterproof pogo-pin connectors can have a pitch as small as 2.5mm. These miniature pogo-pin connectors offer excellent, highly reliable design options for portable electronics designers, meeting stringent size and weight reduction requirements.

Flexibility

Pogo-pin connectors can interface with a wide variety of surfaces as long as the spring pin can make proper planar contact. This broad compatibility removes the singularity of traditional pin-socket connector systems, saving space and significantly reducing production time and costs.

High Current Performance

Some portable medical electronic devices require current capacities of up to 10A. Utilizing advanced insulator technology, pogo-pin connectors can provide higher current-carrying capacity than standard ball technology, thus meeting this demand.

As new portable and wearable products continue to emerge in the medical device market, pogo-pin connectors will evolve to address the unique design challenges posed by these applications. While water damage to portable and wearable medical electronics was once considered inevitable, it can now be prevented through specific design features. Beyond saving critical space and reducing costs, waterproof pogo-pin connectors offer high reliability, which is essential for demanding mobile and wearable medical products.