CAE (Computer Aided Engineering), also known as “Computer Aided Engineering” in Chinese. Huawei Group Director Xu Wenwei once said: Industrial software will become the “pearl” on the industrial crown. CAE software, also known as the most shining “pearl”, demonstrates the uniqueness and importance of CAE in the process of industrialization.

CAE is a technology that uses computers to simulate and analyze designed products to verify whether their various performance indicators have been met. Simply put, it means that computers replace experiments and can simulate all related properties of products such as electromagnetism, thermodynamics, fluid mechanics, etc. Through simulation, we can understand the performance differences of products in different structures and environments, evaluate the advantages and disadvantages of different solutions, and guide decision-making and optimization design. With the emergence of new technologies such as AR/VR, cloud computing, and artificial intelligence, simulation design integrates multi-disciplinary content such as software engineering, computational mathematics, engineering, physics, and product design, and its applications are becoming increasingly widespread. As a one-stop interdisciplinary precision component solution provider, Top-link designs and develops products that involve interdisciplinary fields such as physics, chemistry, and engineering technology. Connector simulation design capability is an important part of Top-link’s R&D capabilities construction, and is also one of the reasons why Top-link is “technologically superior” in the industry.

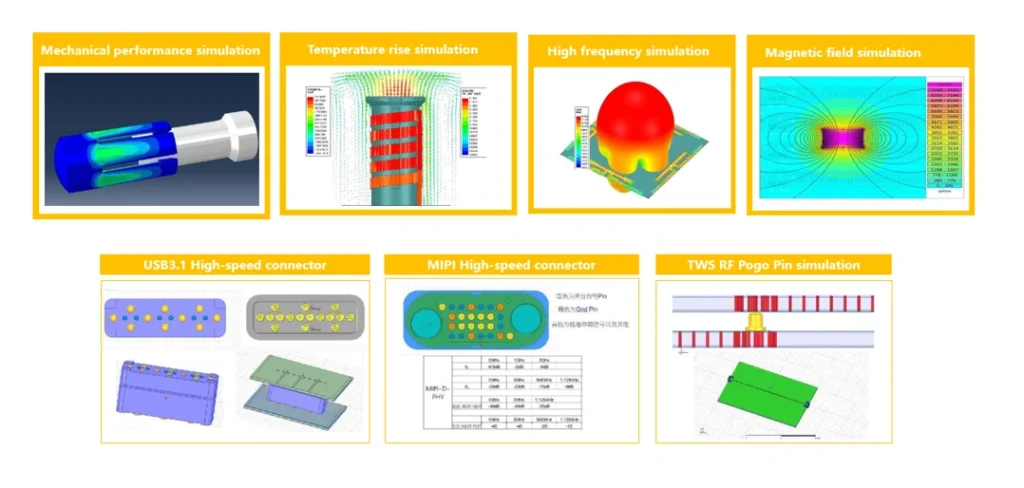

Through R&D innovation and long-term practical accumulation, Top-link has mastered core simulation capabilities such as mechanical simulation, temperature rise simulation, high-frequency simulation, and magnetic field simulation. The R&D engineers of Top-link are skilled in using simulation software to analyze and optimize the performance of connectors in different application scenarios, such as characteristic impedance, insertion loss, return loss, crosstalk, and mode conversion parameters. It is worth mentioning that in the simulation design of high-frequency connectors, Top-link applies the internationally leading HFSS (high-frequency simulation software) to whole parameters design, from geometric structure and material characteristics to analysis, control, and all post-processing, greatly saving engineers’ design time and the company’s equipment, material, and human resource costs. Intuitive analysis settings and advanced analysis control ensure that the design results are achieved in a full- automatic way.

In recent years, Top-link has continuously expanded the industrial field of its R&D, reserving, laying out, and promoting technical skills and products in the industry, which is beneficial for the company to continuously enhance its core competitiveness in connectors and related fields. The complexity and professionalism of connector simulation design require designers to have a high level of technology and knowledge in order to achieve it. Top-link has rich experience in cooperative development with customers in connector simulation design, which can optimize product design and shorten development time. Its professional ability has formed advantages in the industry, allowing the company to accumulate knowledge in the R&D new products in interdisciplinary field, functional iteration, improve product added value, and increase the company’s overall competitiveness.