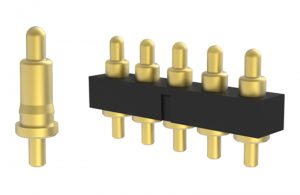

Pogo Pin Characteristics

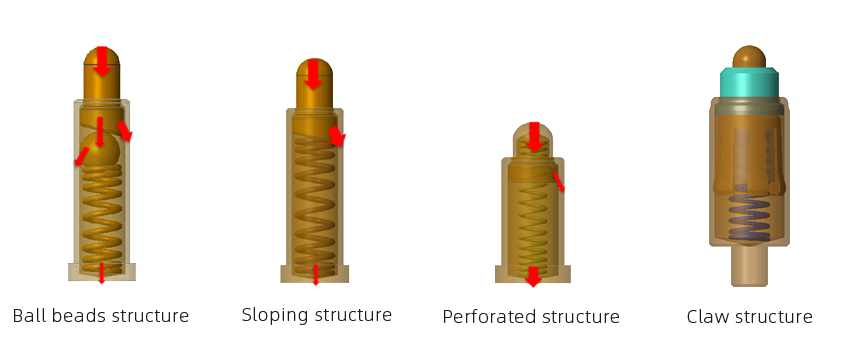

Common structure of pogo pin

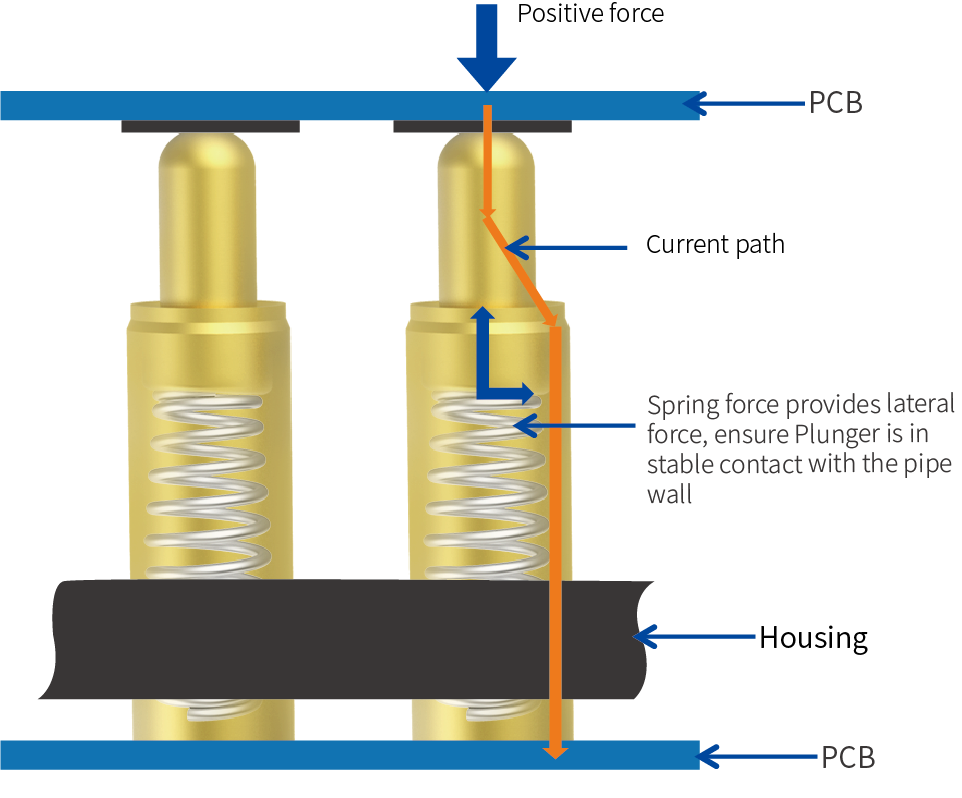

Pogo pin contact principle

Characteristics

- Long service time, 10,000 times

- No tooling fee,easy go customize

- Adjustable and measurable spring force

- Fine pitch

- Flexible manufacturing ways: SMT,plug-in...

- Save space: help mechanical engineer easily allocatecomponents on PCB

- Good performance on RF solution

- RoHS and Halogen Free

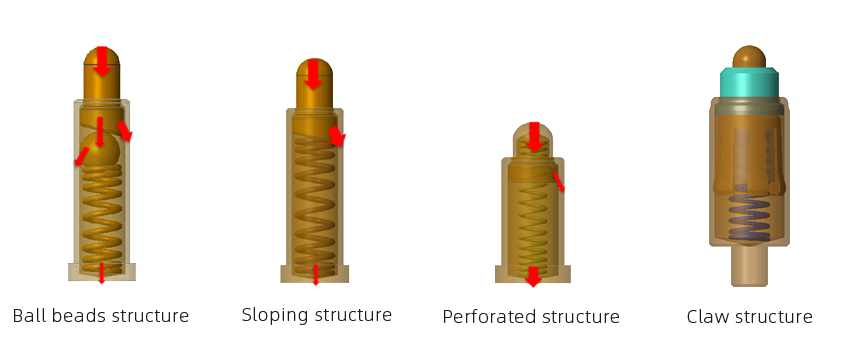

Common internal structure of Pogo Pin

| Structure | Ball beads structure | Sloping structure | Perforated structure | Claw structure |

| Contact impedance | ≤ 10mΩ | ≤ 30mΩ | ≤ 50mΩ | ≤ 5mΩ |

| Long service time | 10000+ | 10000+ | 10000+ | 500+ |

| Recommended working current | 10A max | 10A max | 10A max | 10A max |

| Contact stability | ★ ★ ★ ★ ☆ | ★ ★ ★ ☆ ☆ | ★ ★ ★ ☆ ☆ | ★ ★ ★ ★ ★ |

| Processing cost | ★ ★ ★ ☆ ☆ | ★ ★ ☆ ☆ ☆ | ★ ★ ☆ ☆ ☆ | ★ ★ ★ ★ ☆ |

| Main application areas | Mainly used for charging and condition with certain requirements for vibration and shock | Mainly used for charging or signal transmission of Consumer electronics | Mainly used for signal transmission or grounding antenna,etc. | Mainly used high-frequency,anti-instantaneous,the situation which high-reliability is required,such as base stations,military industries,vehicles. |

| Remarks | The beads increase the internal contacts,the contact is more stable,and the more needle space is required | The most commonly used structure on the market | The space is smaller,but the contact is not stable,the current is easy to run through the spring,and it is not recommended for charging | The needle and the needle tube have multiple contacts to increase the contact stability |

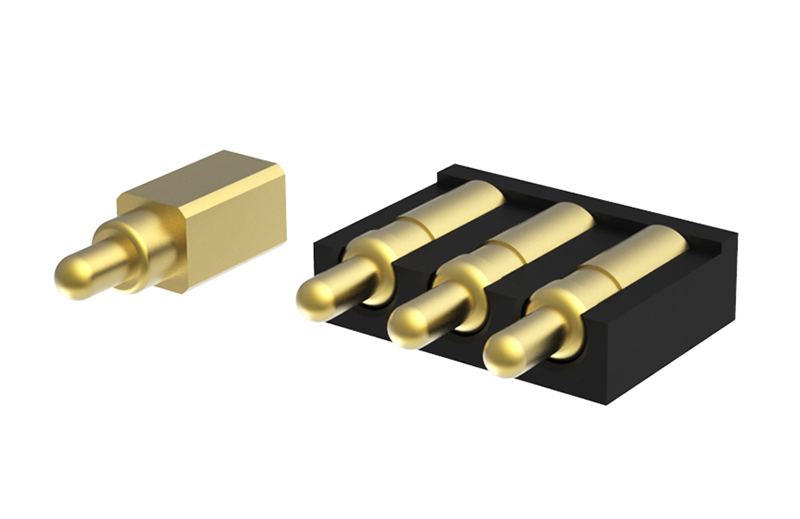

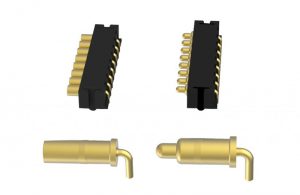

Product Model

| Index | Part No. | L | W | H | Pitch | Number of Positions | Cap | Positioner | L0 | L1 | H0 | Working height | Froce(gf) | PDF |

|---|

| Index | Part No. | L | W | H | Pitch | Number of Positions | Cap | Positioner | L0 | L1 | H0 | Working height | Froce(gf) | PDF |

|---|

| 1 | 100257-2 | 6.3 | 4.4 | 1.71 | 4 | 2 | N | N | 4.4 | 6.1 | 0.63 | 5.1 | 110+30/-20 | |

| 2 | 1001008-2 | 5.2 | 1.5 | 2.5 | 2.54 | 2 | N | N | 3.5 | 4.8 | 1.25 | 3.8 | 150±30gf | |

| 3 | 100001-3 | 6.3 | 4.4 | 1.71 | 2 | 3 | N | Y | 4.4 | 6.1 | 0.68 | 5.1 | 110+30/-20 | |

| 4 | 100005-3 | 7.7 | 3.05 | 2.8 | 2.5 | 3 | N | Y | 3.5 | 5 | 1.44 | 4 | 120 Min | |

| 5 | 100609-3 | 7.7 | 3.05 | 2.8 | 2.5 | 3 | N | N | 3.5 | 5.5 | 1.52 | 4.5 | 135±25 | |

| 6 | 100265-3 | 7.7 | 3.05 | 2.8 | 2.5 | 3 | N | Y | 3.5 | 5.5 | 1.53 | 4.5 | 165±25 | |

| 7 | 100021-3 | 7.7 | 2.87 | 4.21 | 2.5 | 3 | N | Y | 3.75 | 5.75 | 2.15 | 4.75 | 130±30 | |

| 8 | 100514-3 | 7.7 | 3.05 | 2.8 | 2.5 | 3 | N | N | 4.05 | 6.05 | 1.52 | 5 | 90±30 | |

| 9 | 100767-3 | 9.7 | 4.35 | 2 | 2.5 | 3 | N | N | 4.35 | 6.05 | 1 | 5.35 | 70 Min | |

| 10 | 100002-3 | 8.6 | 1.5 | 2.7 | 2.8 | 3 | N | Y | 3.5 | 5 | 1.35 | 4.2 | 120±25 | |

| 11 | 100583-3 | 8.6 | 1.5 | 2.7 | 2.8 | 3 | N | Y | 4 | 5.5 | 1.35 | 4.5 | 130±30 | |

| 12 | 100289-3 | 8.6 | 1.5 | 2.7 | 2.8 | 3 | N | Y | 3.5 | 5.5 | 1.35 | 4.7 | 120±25 | |

| 13 | 100003-3 | 8.6 | 1.5 | 2.7 | 2.8 | 3 | N | Y | 3.5 | 5 | 1.35 | 5.2 | 120±25 | |

| 14 | 100574-3 | 8.4 | 4.4 | 1.75 | 3 | 3 | N | Y | 4.7 | 6.1 | 0.72 | 5.1 | 140±25 | |

| 15 | 100778-3 | 8.4 | 4.4 | 1.75 | 3 | 3 | N | N | 4.7 | 6.4 | 0.72 | 5.4 | 120±25 | |

| 16 | 100557-3 | 8.4 | 4.4 | 1.75 | 3 | 3 | N | Y | 4.7 | 6.4 | 0.72 | 5.4 | 120±25 | |

| 17 | 100290-3 | 9 | 5 | 4.5 | 3 | 3 | N | Y | 5.05 | 6.55 | 3 | 5.55 | 120+30/-20 | |

| 18 | 100634-3 | 9 | 5 | 4.5 | 3 | 3 | N | Y | 5.05 | 6.55 | 3 | 5.55 | 120+30/-20 | |

| 19 | 100466-3 | 7 | 5 | 4.5 | 3 | 3 | N | Y | 5.05 | 6.85 | 3 | 5.55 | 130+30/-20 | |

| 20 | 1101024-3 | 9 | 5 | 4.5 | 3 | 3 | N | Y | 6 | 8.2 | 3 | 6.2 | 200 Max | |

| 21 | 100905-3 | 8.6 | 1.5 | 2.7 | 2.8 | 3 | N | Y | 3 | 4 | 3.2 | 1.35 | 120±25 | |

| 22 | 110375-3 | 9.2 | 1.56 | 2.9 | 3.1 | 3 | N | Y | 3.7 | 5.5 | 2.1 | 4.25 | 175±25 | |

| 23 | 100073-3 | 11.3 | 3.5 | 4 | 4.2 | 3 | N | Y | 5.5 | 7.3 | 1.5 | 6.3 | 100 Min | |

| 24 | 100001-4 | 8.3 | 4.4 | 1.71 | 2 | 4 | N | N | 4.4 | 6.1 | 0.68 | 5.1 | 110+30/-20 | |

| 25 | 100049-4 | 8.3 | 4.4 | 1.71 | 2 | 4 | N | N | 4.9 | 6.6 | 0.68 | 5.6 | 110+30/-20 | |

| 26 | 100760-4 | 10 | 4.4 | 1.7 | 2.5 | 4 | N | Y | 4.4 | 6.1 | 0.72 | 5.3 | 80 Min | |

| 27 | 100594-4 | 10 | 4.4 | 1.7 | 2.5 | 4 | N | Y | 4.4 | 6.1 | 0.72 | 5.4 | 100 Min | |

| 28 | 100637-4 | 10 | 4.4 | 1.7 | 2.5 | 4 | N | N | 4.4 | 6.1 | 0.72 | 5.4 | 100 Min | |

| 29 | 100542-4 | 10 | 4.4 | 1.7 | 2.5 | 4 | N | Y | 4.4 | 6.1 | 0.72 | 5.4 | 100 Min | |

| 30 | 100328-4 | 10.5 | 5 | 6.6 | 2.5 | 4 | N | Y | 5.2 | 7.2 | 5.1 | 6.2 | 120+30/-20 | |

| 31 | 100685-4 | 13.82 | 4.7 | 4 | 2.5 | 4 | N | Y | 5.15 | 7.15 | 2 | 6.35 | 115±25 | |

| 32 | 100385-4 | 10.5 | 5 | 6.6 | 2.5 | 4 | N | Y | 5.5 | 7.8 | 5.1 | 6.6 | 120+30/-20 | |

| 33 | 100938-5 | 17.5 | 6.3 | 7 | 3 | 5 | N | N | 6.7 | 8.2 | 5 | 7.2 | 150±35 | |

| 34 | 100814-5 | 12.5 | 4.4 | 1.8 | 2.5 | 5 | N | N | 4.4 | 6.1 | 0.72 | 5.3 | 80gf min | |

| 35 | 1001033-8 | 18.5 | 3.9 | 2.7 | 2 | 8 | N | Y | 4.3 | 5.6 | 1.35 | 4.9 | 90±20 | |

| 36 | 110414-8 | 17.2 | 5.5 | 3.1 | 2 | 8 | N | Y | 6 | 7.8 | 1.55 | 6.8 | 50±25 | |

| 37 | 100722-6 | 17.4 | 5 | 9.8 | 2.2 | 6 | N | N | 5.4 | 6.9 | 8 | 5.9 | 120±25 | |

| 38 | 10101021960 | 6.3 | 4.4 | 1.71 | 4 | 2 | N | N | 5.1 | 6.6 | 0.68 | 4.8 | 110±30 | |